wire edm machine working principle

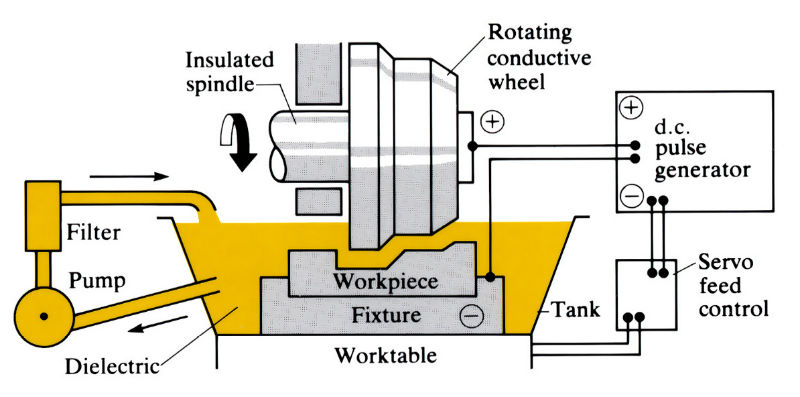

In this sense no electrical conductivity is taking place. The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion.

Electrical Discharge Machining An Overview Sciencedirect Topics

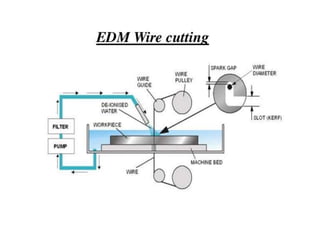

Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin.

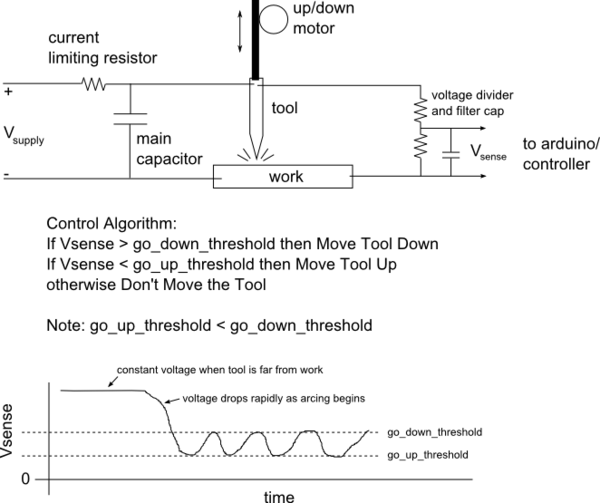

. But by an increase of high pressure the dielectric fluid ionizes into Negative and Positive Ions. As the spark jumps across the gap material is then removed from the. Electrical discharge Machining Working Principle.

The positive ions are attracted to. The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting. This leads to the.

62 Hoang Tat Dat Ward 15 Tan Binh District TP. In the EDM process the tool which is called Electrode and the work-piece are separated by a small gap and both the electrode tool and the work-piece are submerged in a. 0938923778 - 0908021514 Ho Chi Minh Da Nang -.

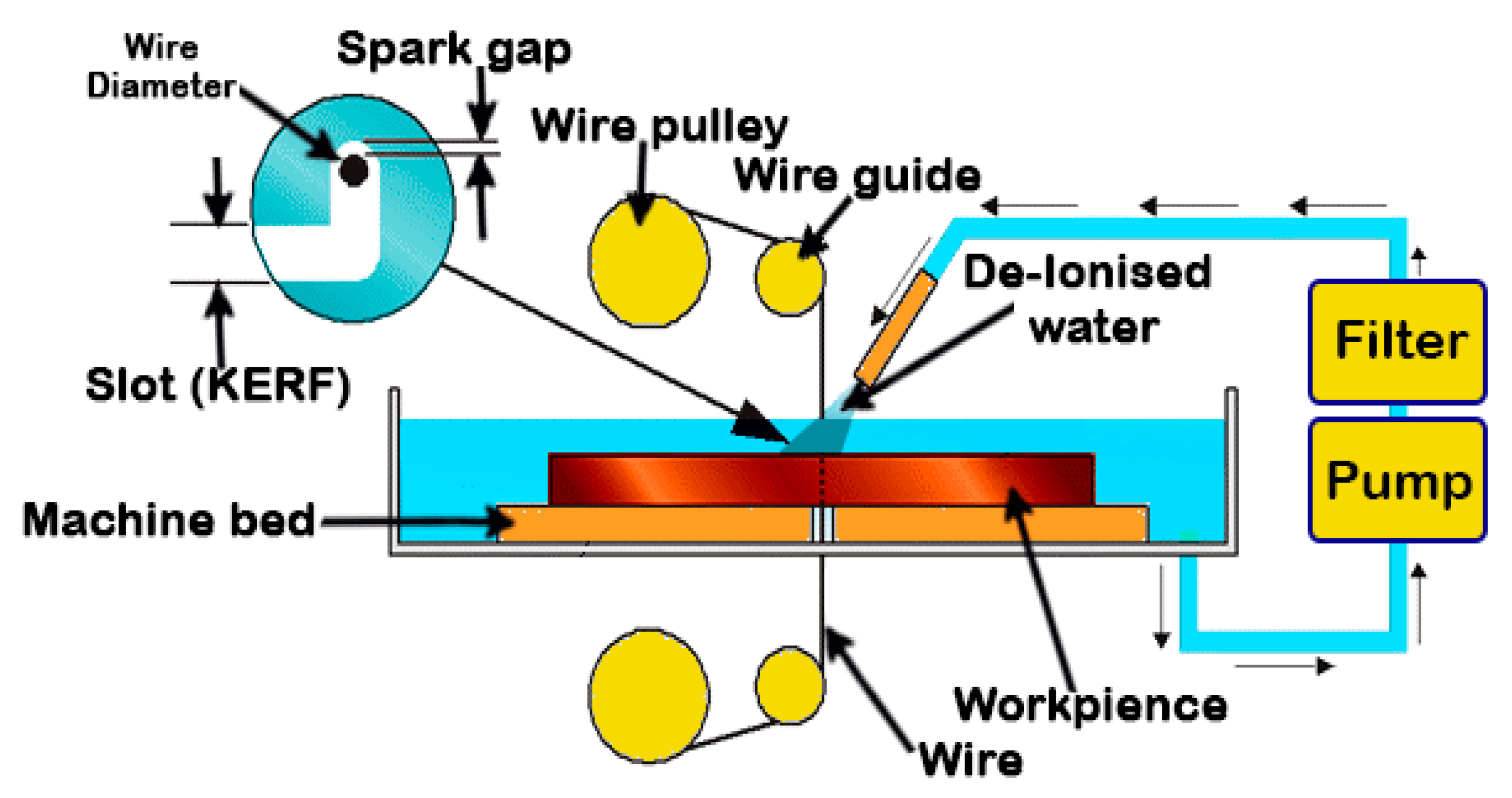

LAM PHU TECHNOLOGY TRADING SERVICE CO LTD. CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo. The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting.

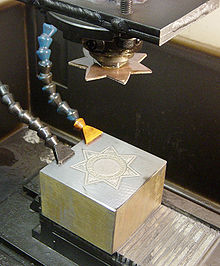

As the electric discharge takes place between an electrodewire and workpiece the thermal energy is generated on a workpiece. Ho Chi Minh Vietnam. EDM Electro Discharge Machining Wire Erosion is a precision engineering process where a work piece is cut through with a strand of wire it creates electrical sparks between the wire and the.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. It works on the thermo-electrical phenomenon. It is suitable for thermoelectric phenomena.

Principle of wire cut EDM. When a discharge occurs between the electrodewire and the workpiece heat energy is generated on the workpiece.

Top 7 Wire Edm Machine Manufacturers Vigert Used Machinery

Applied Sciences Free Full Text Principles And Characteristics Of Different Edm Processes In Machining Tool And Die Steels Html

Working Principle Of Edm Machine

Electrical Discharge Machining Youtube

Electrochemical Discharge Grinding Of Metal Matrix Composites Using Shaped Abrasive Tools Formed By Sintered Bronze Diamond

Edm Past Present And Future Asia Pacific Metalworking Equipment News Manufacturing Automation Quality Control

Electrical Discharge Machining Wikipedia

Short Note On Wire Electric Discharge Machining Wire Edm Please Subscribe The Channel Youtube

Mechanical Engineering Electrical Discharge Machining Edm Principles

Parametric Optimization Technique In Wire Cut Electrical Discharge Machining An Overview Semantic Scholar

Edm 101 Electrical Discharge Machining Basics Engineering Com

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Pdf Operation And Maintenance Of Cnc Wire Edm Machines

What Is Wire Edm Electrical Discharge Machining Xact

Precision Wire Edm Services丨wire Cut Edm Machining丨dek

Wire Edm Find Suppliers Processes Material